Control systems are special devices and computer programs, which facilitate their factories to work in a better and safer way. These are systems that monitor and manage machines producing items such as cars, clothing and mobile phones. They are essential to ensure that these gears are running. In case of a problem, these systems can rapidly power down the machines so everyone will stay safe and no accidents will occur. QingjunThis firm, called Qingjun has built a solid reputation helping factories with these control systems. They offer the software technologies that enable high-speed, safe and energy-efficient production of products in the modern manufacturing society

What Are Control Systems?

There are many different components working to create a control system. It has a major component known as sensor. Sensors are devices that can tell when something about the machines they are attached to has changed—such as how hot or cold it is, or if there is too much pressure. If the sensors detect an anomaly, they send a message to the controller. The controller is the brain of the control system. It analyzes the information it acquires, then it gives feedback to the machines so that they can also improve their way of working. It can occur on its own or a person may assist in the operation of machines through a computer or similar device from far away.

Control Systems for Factories

Control systems is a way that helps a factory to make it work faster, safer and more efficient. They regularly inspect the machines, recheck if some mistake happened to be done by them can be corrected in no time. It can tell right away that the machine is not functioning properly if there is a malfunction; the programmable logic control system will adjust accordingly. The machines can also alter their operational parameters based on the sensor data they receive. For example, if an oven is overheated the sensors will tell the controller. The controller can then cold it automatically. This guarantees that the products are being made properly and is key in their ability to pass quality control tests; they cannot submit faulty products or the factory will fail.

Keeping Control Systems Safe

Control systems must also be protected from external treats as well. In the same way that we lock our doors to keep the home safe, plc system of other critical infrastructure must be safeguarded. Hackers must be prevented from gaining control of these systems they could halt the machines in their tracks, or produce sub-standard goods that would pose potential danger to humans. Also, These hackers may even try to steal vital information that might damage the factory and also put the lives of the people dependent on their products at risk. And of course, if the systems aren't safe this could also mean that people's lives are in danger -particularly in places where otherwise machines can be really dangerous when not properly controlled. Qingjun is passionate about safety, and he creates highly secure control systems that other hackers like him find them too difficult to compromise the factories and put their workers and produce at risk.

Various Kinds of Control Systems

Various factories employ different types of control systems – all designed for their respective use cases. Some of these systems include:

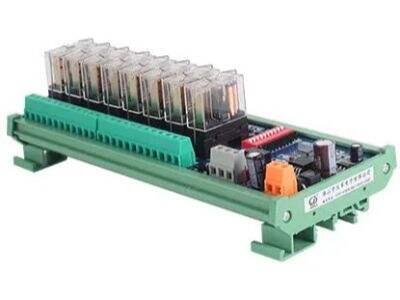

PLCs(Programmable Logic Controllers): small computers used to control machines in factories. We see PLCs used every day in a system like the robotic arms that weld or paint cars you often find at car factories. They more closely align the manufacturing process.

Supervisory Control and Data Acquisition (SCADA) Systems: These systems collect data from sensors and transmit it to human operators so they can validate this data. Of particular interest in terms of safety and damage to the environment SCADA systems are often used in the oil and gas industry for monitoring pipelines, preventing leakage.

Distributed Control Systems (DCS) — These are used for industries like factories, which require multiple machines to work together. The chemical industry has a lot of DCS controlling systems machines that mix chemicals and make various products. They work to guarantee that the process of carrying out production is successful and safe.

The Future of Control Systems

Technology will continue to evolve leading to more advanced and sophisticated control systems as well. Here are a few exciting new ideas for the future.

Artificial Intelligence (AI) — AI can enable control systems to act autonomously and use information from sensors. In other words, machines would be able to learn and progressively get better without the daily manual labor.

IoT (Internet of Things) — Allows every machine talk to each other. For control systems, this means different machines can now communicate more effectively with one another during the manufacturing process to help drive efficiencies.

Augmented Reality – The ability to use this technology in order to allow workers view all the relevant SCADA information. The technology uses augmented reality to allow workers to see data in real time, meaning they can make right decisions faster when things go wrong.

Therefore, the control systems play a vital role in factories as they are the maintaining machinery of all items which work together and prevent secure and high productive manufacturing progress. Factory is so safety, make high quality products with Qingjun's security service. And as new technology emerges, these systems will only have more room for growth to further assist in safe and productive factory operation.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU TH

TH TR

TR GA

GA MK

MK HY

HY KA

KA BS

BS MN

MN