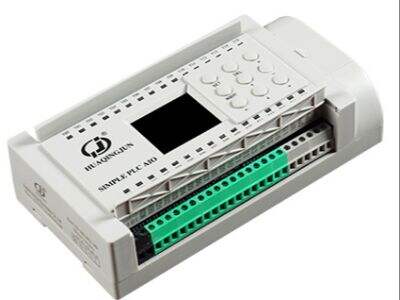

Guess what I found out, they have this thing called a Programmable Logic Controller PLC. In the case of industry, it is a tool to help control machines at many different locations such as factories and other industries. We at Qingjun are not going to do PLC-Programmable Logical Controller tutorials on how to use them.

A PLC is a kind of small computer that commands all the machines. It can control anything from motors that move machines, to pumps that move liquids and even robots that perform certain functions. PLCs are specifically designed to function reliably in harsh environments anywhere from dust-filled factories to deep inside a mine. They are built to be very durable and function safely without fail.

How to Program a PLC?

It can seem intimidating at first to program a PLC, but once you start experimenting with it — it should be easy. You write the test case — the input and expected outputs — before you start, so that tells you how you want to be perform or in which way you want the PLC to react.

So in terms of programming a PLC, what we are really discussing is the writing to-do-lists that instruct it how to react when some things presented or felt by the machine. Inputs are things that the PLC detects. I describe inputs as a sensor that detect changes in the world, like a switch that can be on or off, and tons of things. Outputs: The PLC system performs outputs to the actions in response to the inputs. Outputs from the PLC may be moving motors, opening or closing valves or turning on lights.

Ladder Logic is one of the many methods to program PLC. This approach to instruction is very easy for novices because it employs pictures and symbols.

Keeping Your PLC Working Well

PLC s are one of the main work-oriented electronic equipment and managing them properly is vital to do well in this job. Providing regular maintenance on machinery can prevent issues and keep machines running hassle-free.

There are a number of ways in which you can take good care of your PLC logic controller. You should probably regularly save or backup your program somewhere if you are able to, so that means keeping track of a copy of all your work in case shit goes wrong. You should also keep an eye on the inputs and outputs to ensure they are functioning properly. The device requires cleaning like with the duster and dirt. Furthermore, the PLC should be stored in a dry and dust-free area so as not to get wet or muddy.

Applications of PLCs in Various Industries

They are employed in a variety of jobs and industries, including manufacturing, mining, and energy production. Take the example of a factory — where a PLC can be used to control machines which produce products, so that everything works efficiently and continuously.

PLCs are used to control large machinery deep underground in the mining industry, where conditions can be especially harsh. They also help to control ventilation systems as well, providing workers with clean air to breathe while they are working. For example, in energy sector PLCs are utilized to control machines which produce electricity so that the power grid behaves stable and dependable for everyone.

How to Become a PLC Expert?

There are lots of ways to get good at PLC. Here at Qingjun, we have many forms of courses to help you learn from scratch or if you are already a beginner in the field of PLCs.

Tons of resources are available online, including videos and forums where people communicate their experiences with PLCs. The more you practice different things in PLC programming, the more you will get knowledge and experience.

So, to conclude we can say that PLCs play a vital role and are used in many works and fields. It is enough to say that knowing what a PLC is, how you program it and keep the magnificently running Factory is an important element of your task as we manage great machines and processes entirely accurately. By learning how PLCs are used and working to master them, you can position yourself for major roles in professions that use this incredible technology.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU TH

TH TR

TR GA

GA MK

MK HY

HY KA

KA BS

BS MN

MN