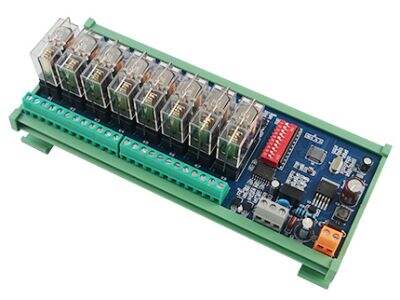

De er like ubeskrivelige som Programmerbare Logikkontrollere, også kjent som PLC. En PLC er en miniatyurretning som gjør at maskiner fungerer slik de skal. Den gjør at ting går glatt og brukes til å operere ulike prosesser. I denne posten skal vi presentere ti avgjørende faktorer du bør ta hensyn til når du velger den riktige pakking-PLC for ditt program.

10 ting å overveie før du velger en PLC

Formål: Det første og viktigste du må se på er hva du skal bruke PLC til. Skal du bruke det i en bilfabrikk hvor biler monteres? Eller kanskje noe for en fødevannsband som transporterer varer fra ett sted til et annet? Det kan også være for å styre trafikklys som hjelper biler og mennesker til å navigere trygt.

Det må være kompatibelt: Deretter må du sørge for at den PLC-en du skal bruke, for eksempel programmabel logikkontroller, er kompatibel med maskinen du skal bruke den til. Det er litt som å sikre at to venner kan spille sammen pænt. Du vil også ønske å sørge for at de kan snakke med hverandre og kjøre på samme type strøm.

Hukommelse: PLC har en hukommelse, akkurat som en datamaskin. Den lagrer viktig informasjon og kommandoer. Avhengig av hvor kompliserte oppgavene skal bli, avgjør hvor mye hukommelse du ønsker.

Hastighet: En annen viktig valgspørsmål å diskutere er hastigheten til PLC-en. PLC, som en programmérbar kontroller, må være rask for å registrere data og sende kommandoer. Tenk deg at hver gang du klikket på noe, tok datamaskinen din evigheter å svare. Du ønsker at din PLC skal være rask slik at du kan ha en glad prosess.

Nøyaktighet: Nøyaktighet er nøkkelen, og hver eneste detalj teller. Finn en PLC som kan måle ting, enkle ting, hvor nøyaktighet teller, som tid og avstand.

Inndata/Utdata: Overvei hvor mange sensorer, skruer og andre enheter som må koble til PLC-en. Jo flere inn- og utdatapunktene en PLC har, jo flere enheter kan den operere sammen med dem.

Samtidige funksjoner: Det kan hende at du oppdager senere at du trenger mer funksjonalitet på maskinen din. Hvorfor det er bra for deg å velge en PLC som kan vokse og tilpasse seg dine behov. Dette hjelper deg mot å måtte kjøpe en helt ny PLC senere.

Programvare: Se hvilken programmeringsprogramvare som er inkludert i utviklingen av PLC-en. Er den brukervennlig? Denne programmeringsprogramvaren vil gjøre det enklere å kode og kunne spore ned eventuelle feil som kan oppstå.

Støtte: God støtte for din industrielle plc-kontroller er veldig viktig. Forsikre deg om at PLC-en støttes av et selskap som gir deg rask hjelp og svarer på dine spørsmål. Du bør kunne kontakte dem når du trenger vedlikehold og reparasjoner.

Pris: Til slutt, overvei prisen på PLC-en. Prisen er avgjørende for å passe inn i din budsjett. Men gjør heller ikke feilen å velge den billigste alternativet hvis du får lavere kvalitet.

Hva bør du se etter i en PLC?

Wow. Les også: 10 ting å ta med i betraktning når du velger en PLC. Under er noen punkter som alltid er relevante for en god PLC.

Pålitelighet: Din PLC bør være pålitelig og utføre godt kontinuerlig under utfordrende forhold. Dette er en av måtene vårt daglige liv fungerer på, og hvis det går ned, kan det føre til store problemer.

Enkel å bruke: Din PLC bør være enkel å programmere, operere og vedlikeholde. Du trenger ingen høygradig spesialisert utdanning eller ferdigheter for å sette den i bruk.

Sikkerhet: Din PLC må oppfylle sikkerhetsstandarder og forskrifter. Dette hjelper med å forebygge ulykker og holde både utstyr og de som jobber med det trygt.

Kompatibilitet: Som nevnt over, bør din PLC være kompatibel med den maskinen eller systemet du planlegger å bruke den med. Dette holder alt sammen å spille og flyte sammen.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU TH

TH TR

TR GA

GA MK

MK HY

HY KA

KA BS

BS MN

MN