In the industrial control system, Programmable Logic Controllers (PLCs) have become an essential element. These are computers used to control the machinery and equipment in factories, PLCs work as brain of a machine, between different components like sensors actuators outcomes or communication developed. PLCs, on the other hand, are programmable and can perform definite tasks; hence really helpful in automatically controlling or monitoring machines used across industries.

PLC Based Applications for FA: Bettering Efficiency and Productivity in Manufacturing

The PLC applications encompass one of the integration points which are central to maximizing efficiency and productivity in modern manufacturing. Years back, to automate manufacturing processes requires tons of manual work. But with PLC applications, everything is done quickly; the cost of labor decreases and in addition to quality at least time and money are saved as well.

PLCs specialize in performing tasks that need to be performed precisely and accurately, work which is actually hard to do manually. These applications do repetitive work 24/7 without getting tired and can be at it continuously with no mistakes.

PLC Applications in Industry Control Below is the list of extremly versatile PLC applications that a control engineer needs to know.

The versatility of the PLC applications in industrial control systems is simply incredible. In automotive, pharmaceuticals, food production, chemical industries and textiles as many others.

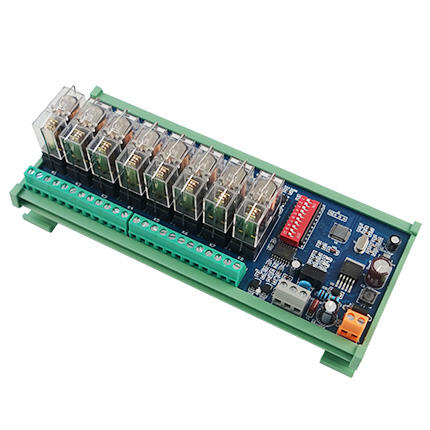

PLC applications gain their versatility from being able to interact with many types of devices such as sensors, actuators and controllers. Beyond that, they could be networked together with different PLCs to direct massive systems. Industries entrust PLC applications to control over a wide range of industrial processes from small-scale machinery to large industrial complexes.

Realizing the Power of PLC Solutions for Smart Factories & Industry 4.0

PLC applications continue to expand rapidly due to surging demand for smart factories and Industry 4.0 Smart factories call for the implementation of high-end automation technologies that can cut costs and improve operations. PLC applications are the key to creating smart factories with high levels of automation, data acquisition and communication.

These apps can be leveraged to build smart systems and make remote monitoring, control Smart factories use these systems to streamline manufacturing operations and remove inefficiencies. Furthermore, PLC applications can be combined with artificial intelligence and machine learning algorithms to build solid control systems for complex manufacturing functions.

The Diverse Applications for PLCs and how they affect Industrial control Systems

The impact of PLC applications in industrial control systems has been so remarkable. It has revolutionized the functioning of industries as it provides an automatic and systematized way to control processes and machinery.

PLCs are expanding into wider ranges of applications. They are very important in process control, motion control and sequential logic controls. This means the implementation of PLC application represents a pivotal moment within industrial control systems - with implications for improved accuracy, faster production rates and reducing waste.

In addition, PLC programs are used to collect live data from sensors for patterns in order to maximize performance of a process. This grants the plant operator with deeper manufacturing process insights that drives increased production efficiency while reducing downtimes.

To sum up, the usage of PLCs offers new control, communication and automation capabilities to industrial manufacturing. PLC applications been used to the stir of smart factories and refined processes that dramatically reduce costs, while improving overall efficiencyand productivity. The adaptability and flexibility PLC applications offers, had been very helpful in helping the industries to realize their primary objectives of supporting customer requirements while maximizing profits.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU TH

TH TR

TR GA

GA MK

MK HY

HY KA

KA BS

BS MN

MN