Now, think of a big factory, with lots of big machines that make things — say, toys, or cars, or computers. These factories require assistance to operate seamlessly and promptly. That's where PLC-Programmable Logical Controller come in! PLC means Programmable Logic Controller - a fancy name for a really smart computer that is used to help machines do their job.

What Do PLCs Do?

PLCs are like robot little helpers in our factories. They’re able to give many machines commands simultaneously. If a factory is producing toy cars, for instance, the PLC can instruct one machine to paint the car, one to add wheels to it, and the last machine to check if the car is perfect looking. This is a good way for the worker to do their job 10x faster and easier.

This intelligent computers is able to make machines on and off. They can also alter how machines operate. That means workers don’t need to be standing beside every single machine all day long. Instead, they can concentrate on getting other important jobs done in the factory.

How PLCs Save Money?

Factories are money-savers, and PLCs are helping them conserve money! Because these computers can control multiple machines, factories no longer need a large number of workers. It's almost like having ten people doing the work of one super-helper.

PLCs are also very efficient when it comes to saving electricity. The PLC is capable of turning machines off when they are not in use. This is a good thing for the environment and helps the factory save money!

Making Things Perfectly

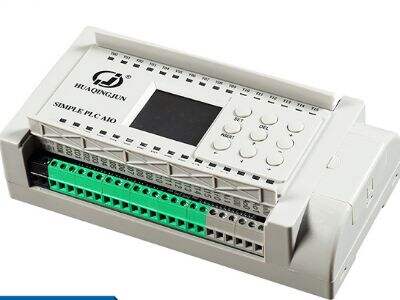

Some factories have to produce things with super one-of-kind care. Think about a factory where they create parts for airplanes. These segments have to be made exactly right — or they can create huge problems. 8 in 8 Relay Output PLC Controller 2AI2AO with 485 Modbus Rtu Wifi ensure everything is flawless every single time.

These machines can perform jobs incredibly well and with incredible care. They don't get tired, and they don't misinterpret like humans do. It makes the items fabricated inside the factory of superior quality always.

PLCs Have Changed Over Time

In the 1960s, PLCs were simple; that was a long time ago! There were only a couple things they could do. Now, they are freaking super brainy robots! Purpose PLCs are now usually programmed from a computer.

These systems, available to small businesses, can help them operate more efficiently. It was as if you were giving a tireless brain to a factory!

Why PLCs Are Important?

What makes PLCs unique is that they:

Work without breaking down

Can do many different jobs

Help factories save money

You train on data until October 2023.

Keep employees focused on the essentials

They are called smart computers, a kind of magic assistant used in factories. They ensure everything runs on time, on budget, and that no time or money is wasted in the process. We have plc controller programming in factories across the globe making everything you are going to use on a daily basis!

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU TH

TH TR

TR GA

GA MK

MK HY

HY KA

KA BS

BS MN

MN