Ensuring the reliable inter-device communication within manufacturing floors is vital for consistent and smooth operation of factories in industrial automation. The HMI Modbus RTU is an essential workhorse, which allows this information to be exchanged by other protocols. This protocol is crucial for connecting human-machine interfaces (HMIs) with remote terminal units (RTUs), as well other industrial equipment, optimizes workflow reporting capabilities and ensures that the entire network operates in unison to improve factory productivity.

If there is a heart in the factory floor, this will be real-time data transfer. HMI Modbus RTU Integration facilitates interaction between operators and machines to allow users monitor, control or diagnose equipment from afar through an intuitive HMI interface. Operators can update settings and process records, set alarms, monitor performance statistics by connecting HMIs directly to RTUs via the reliable Modbus RTU protocol. This real-time and actionable information reduces the decision-making time, thereby reducing downtime and increasing factory floor operational productivity.

Modbus RTU, a member of the wider family of Modbus communication protocols. It is important and also simple & reliable in most universal sense. Due to it being a compact, binary formated data model; JSON can transfer information easily and efficiently over slow channels such as serial communications. Also, its vendor-neutral design with Modbus RTU comes in handy as it acts like a common language between products of various companies which is a significant reason why this protocol largely dominates the industrial automation sector. The use of this protocol is the means by which HMI MODBUS RTU integration provides an integrated ecosystem for better communication between devices allowing predictive maintenance and top resource optimization.

HMI Modbus RTU technology actually utilizes a more clever, yet simple communications framework just below the surface. The Modbus RTU protocol is a polled or non-conflicted master/slave system in which an HMI plays the role of master sending commands and requests, while RTUs / slaves respond as needed against. Under this pattern, these interactions are based upon a strict set of function codes that map to read or write operations targeting specific data points in slave devices (such as coils, discrete inputs, holding registers and input registers). This disciplined data management technique, in turn enables tight control and monitoring the performance of every piece of equipment which works within a factory system.

HMI Modbus RTU for factory operations across the board has much possibility to offer. Centralized control and monitoring through an intuitive HMI gives operations personnel a complete picture of their operation, allowing them to quickly recognize inefficiencies and take corrective measures. Complex information can be easily represented in graphs, charts and alarms transmitted on advanced HMIs so that the data is visualized immediately showing you where your critical problems area sooner than later. Moreover, HMS Modbus RTU has the ability to develop automated responses and routines based on sensor feedback, therefore HMI will be able to auto configure processes leading minimal manual work which eventually increases productivity inside factory.

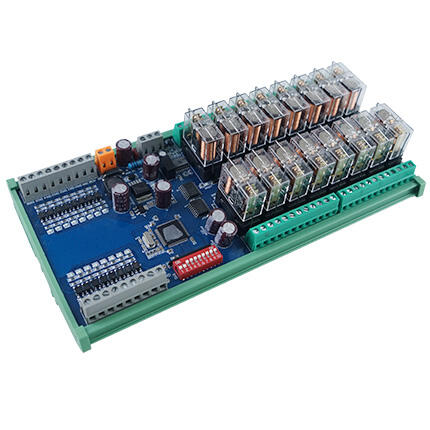

The products include RS485 The products of RS485 are 232 Ethernet modules and analog inputs modules analog outputs module, PLC, HMI, relay modules, AC/DC amplifier board, switching power supply etc. There numerous applications parking systems, such as. The greenhouse ETC Induction, packaging system. Traffic lights system. streetlamp control. Smart home system. Robot control. Control of water spray. manufacturing line includes an SMT mounter that is equipped with automated wave hmi modbus rtu automatic packaging machines. It also includes an entire set of top-quality control equipment. means that every product image "carefully and with care" allow customers buy and use without hesitation. We can also provide a variety of options to meet the needs of our customers' systems.

Huaqingjun, hmi modbus rtu industrial control manufacturer. company, which has seen 20 years of expansion has grown become 3000sqms large-scale enterprise that focuses on the production, development sales Internet Things. We also have an R D department which can provide technical solutions customers. And our company has 4G module, Ethernet module, WIFI module, Bluetooth module, simple programmable PLC integrated machine RS485 communication module industrial relay module PLC AC/DC power amplifier module and other important products.

Patents have been granted for our inventions. company has also received honors like "National Expertise in High-Tech" and "Guangdong Province a creditworthy and contract-abiding Enterprise". products have also passed the "IS09001:2015 quality assurance certification", and passed the FCC, CE, ROHS, ISO and other certifications. The company has gathered many R D talents who have academic degrees in fields of electronic engineering, automation communication, many other fields. The group of experts works closely with customers to hmi modbus rtu the overall customer experience. also support large numbers of companies as well as companies that manufacture equipment. We develop more competitive industry solutions for customers. company also is equipped with a highly efficient and intelligent production facility. Each product is equipped with sturdy and reliable chips that offer top performance. Customers can use and purchase with confidence.

company holds variety of national patents and has also won honors like "National High-Tech Expertise" and "Guangdong Province Contract-abiding and Credit-abiding Enterprise". The products have been inspected and certified "IS09001:2015 Quality Certification". has received CE, ROHS, FCC, SGS etc. certifications. And the company has gathered an impressive number of highly skilled R D experts with academic backgrounds electronics engineering, automation Engineering, communication engineering etc. team of experts dedicated serving the end-users, continually improving customer service, and is able serve most hmi modbus rtu of Things companies and equipment manufacturing firms.

As you can see, the implementation of HMI Modbus RTU protocols provides many advantages in industrial environments. The first is that the standardization offered by Modbus RTU effectively reduces system integration work and streamlines setup time, which means reduced expenses arising from potential compatibility problems. The extensibility of Node plus its large adoption in the industry makes this a solution that is supported for years and can be quickly maintained. The second is the fact that because of how efficient the protocol is with dealing data, it reduces time delays and improves control reliability which makes a world huge difference in applications where timing matters. What is more, its scalability also ensures their systems can easily expand or be amended to developing industrial requirements for Modbus RTU networks. Editorial: In addition, HMI interfaces create a safe work space by alerting operators of emergency or hazardous activities immediately and therefore enabling the immediate corrective action required.

Finally, the integration of HMI Modbus RTU is a keystone for any industrial automation strategy. Its capacity to orchestrate intricate systems, improve communication efficiency and empower operators with real-time insights makes it pivotal in maximizing productivity and increasing operational excellence within factories. As more industries in the world adopts to digital transformation, HMI Modbus RTU technology integration will likely continue taking center stage; propelling smarter factories of tomorrow.